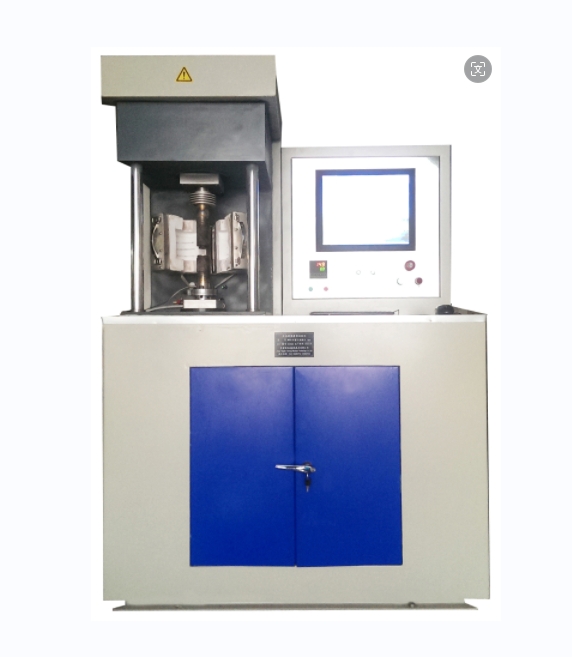

MGS-2T high speed end face friction and wear tester

Brief introduction:The high speed end face friction and wear tester is developed and made by

First, product introduction

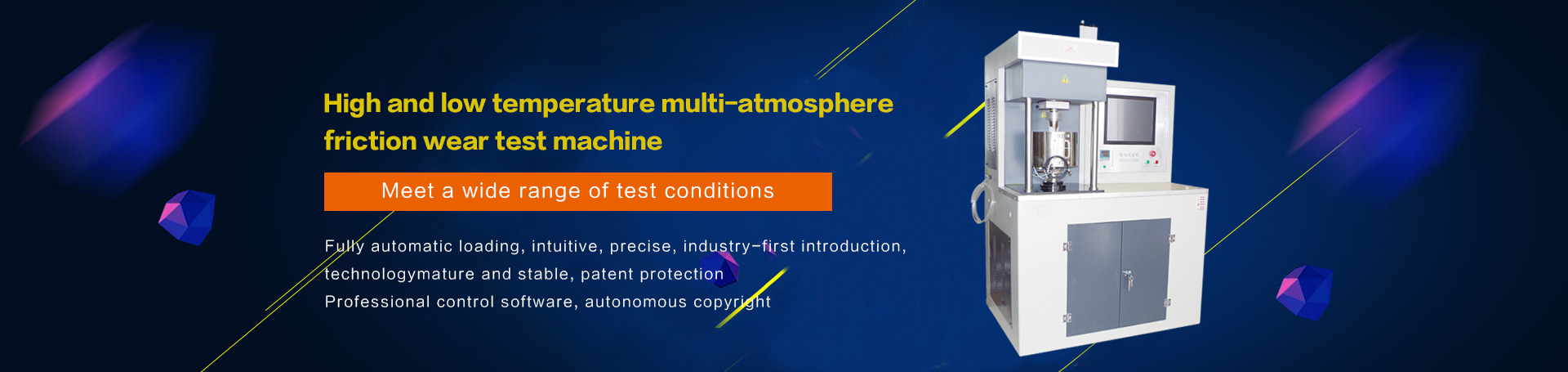

The high speed end face friction and wear tester is developed and made by the customer special requirements. The machine is mainly used to realize the friction and wear of the test end specimen at the high speed, for example, the friction and wear simulation test of the high-speed rotating end face sliding bearing, the mechanical seal ring and the parts with similar working conditions. The friction and wear tester is universal and is also an ideal device for teaching and research projects.

In the form of sliding friction, the machine can evaluate the friction and wear properties of lubricants, metals, plastics, coatings, rubber, ceramics and other materials under large contact pressure, wide speed range and variable lubrication conditions.

The machine has the characteristics of flexible computer control, many kinds of friction pairs, large speed control range, capable of simulating high temperature environment, high automation and easy to use adjustment.

Three. Technical indicators

Serial number | entry name | Technical indicators |

1 | Test load | 0~2000N(indication error + 1%) |

2 | Main motor power | 4KW |

3 | Speed (stepless speed regulation) | 10~4500 r/min |

4 | Surface temperature measurement range | Room temperature to 500 degrees centigrade (indication error + 2 c) |

5 | Temperature control range of oil tank | Room temperature to 200 degrees centigrade (indication error + 5 C) |

6 | Friction torque measurement | 0~20N?m(indication error + 2%) |

7 | Sample size | Customized according to demand≤125mm |

8 | Power Supply | Three-phase380V 40A |

9 | control computer | Special data processing computer, 19 inch liquid crystal |

10 | Data card | ISO/GBcommunication |

Four. A brief introduction to the structure

1. The host computer uses split control and uses split off technology to effectively realize the stable and reliable system of the host's own system, and at the same time realizes the rapid establishment of connection between the host and the control system.

2, adopt floating technology to effectively reduce the unevenness of friction, and extend the technology to provide different docking fixtures according to the sample requirements.

Five. Confidentiality of technical information and information

1. This technical scheme belongs to the technical information of our company. The user shall bear the obligation to confidentiality of the technical information and information provided by us. No matter whether this scheme is adopted or not, the terms are valid for a long time.

2, we should also undertake confidentiality obligations for the technical information and information provided by users.

Tel:+86-0531-85860713,+8615508660930

WeChat/WhatsApp:+8615508660930

Skype:+8615589966455

QQ:1538151698

The contact:Janna Tang

Email:cnjntest@163.com