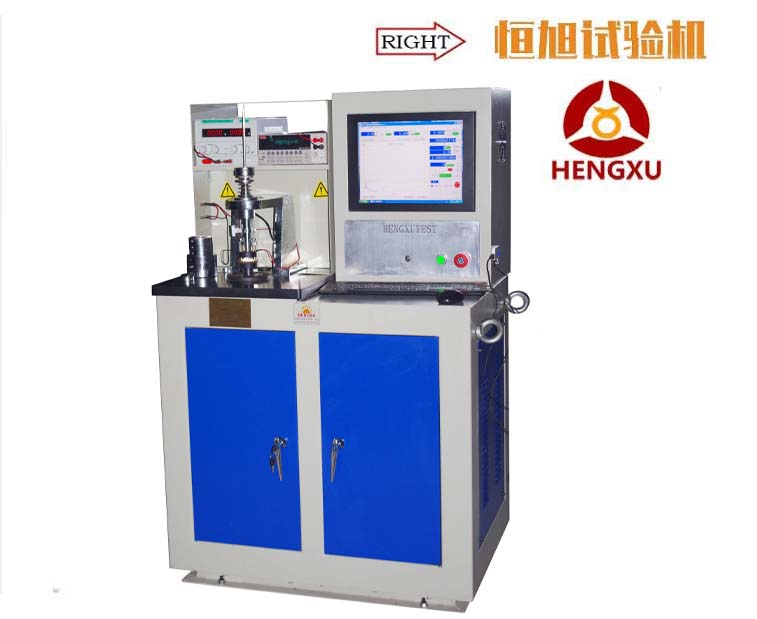

MM-03P type small load flow friction and wear tester

Brief introduction:The machine has independently developed a new generation of friction and w

First, product introduction:

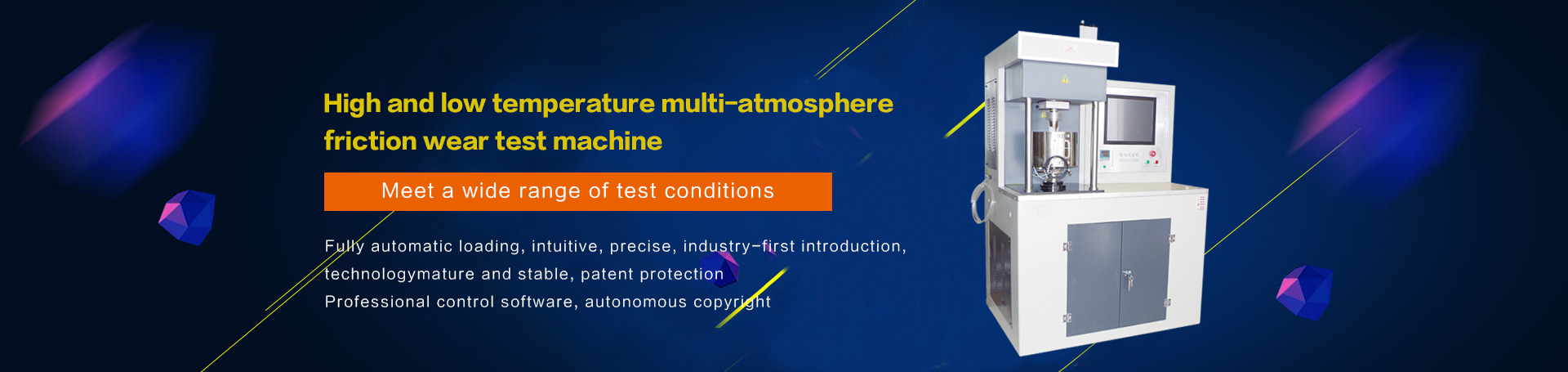

The machine has independently developed a new generation of friction and wear testing machine for our company. Under certain contact pressure, it can complete the tethered disk friction test. The motor drive disc rotates with the relative stationary bolt in the electric state, and the friction force, the contact voltage, contact current and contact resistance are collected in real time through the sensors. The signals of wear and tear to the computer control system are recorded and displayed in real time by computer. The instrument is mainly applied to study the tribological properties and mechanism of materials and coatings under the condition of small current carrying electricity.

The test machine is a delicate type equipment, which can realize the form of friction pair: the routine is the pin plate fixture, and the replacement fixture can realize many kinds of friction pairs, such as the ball disc and the end face. The machine has the advantages of smooth running, convenient control, high measuring precision and high degree of expansion of the friction pair. It is a friction and wear testing machine with Heng Xu's innovation. Low load upgrade products.

Two, the main technical indicators

Serial number | project | Technical indicators |

1 | Test load | 50~5000g |

2 | Loading mode | Weight loading |

3 | Support mode | Single fulcrum (fulcrum adaptive) |

4 | Main motor power | 400W |

5 | Maximum speed (servo stepless speed regulation) | 3000 revolutions / points |

6 | Measurement range of friction torque | 0~1500N?mm(±0.2%Fs) |

7 | Friction pair | Pin (bolt) disk friction |

8 | Friction pair bolt size | Φ3mm~Φ5mm |

9 | Sample size | Φ45mm |

10 | Measurement accuracy of contact point current | 0.01mA |

11 | Measurement precision of contact point voltage | 0.01mV |

12 | Power supply | AC and DC dual power supply from 0 to 30V/0 to 20A |

13 | control mode | It can realize combination control of speed, time and friction. |

14 | Host protection | The host has the early warning of the various test parameters |

15 | data processing | Real time monitoring software is used to collect data in real time and process related curves. |

16 | Special data processing computer | Standard configuration |

Three. Confidentiality of technical information and information

1. This technical scheme belongs to the technical information of our company. The user shall bear the obligation to confidentiality of the technical information and information provided by us. No matter whether this scheme is adopted or not, the terms are valid for a long time.

2, we should also undertake confidentiality obligations for the technical information and information provided by users.

Four. After sale service

The quality guarantee period is one year from the acceptance, lifelong maintenance, free service within one year, free installation and commissioning of new machines, free training operators.

1, the test equipment provided is in line with the current national standard or industry standard, so as to ensure the advanced technology and reliability of the test equipment.

2. The required spare parts and accessories are supplied perennial.

3, product perennial technical support, product maintenance and repair within 24 hours to provide solutions, if necessary, on-site solution to arrive within 72 hours;

4, the software is upgraded free of charge in life.

Tel:+86-0531-85860713,+8615508660930

WeChat/WhatsApp:+8615508660930

Skype:+8615589966455

QQ:1538151698

The contact:Janna Tang

Email:cnjntest@163.com